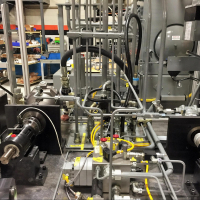

Test systems are a major component within Flodraulic Group's group product portfolio. Turnkey systems, complete with controls and data acquisition integration, are offered for a range of applications including structural, failure and product testing.

Whether in an R & D lab or end-of-line production facility, Flodraulic Group's test systems are proven and supported worldwide.

Expertise comes in six major disciplines...

Development Testing (R&D):

Flodraulic Group can team up with your engineering staff for testing a new concept, developing a new product or adapting/changing an existing product. Flodraulic Group specializes in dedicated or "one-off" testing with very flexible test systems.

Application Testing Processes (ATP):

Flodraulic Group's application test system assemblies can be used to determine product functionality and that it meets the parameters outlined within specified operational targets. The Flodraulic Group specializes in this "one-off" testing done by hand on very precise parts or systems and are generally designed and built for your specific requirements.

Qualification Testing Process (QTP):

Qualification testing is used to determine if the product, once developed through the ATP testing, is in fact within the required specifications. These test stands can be used by the OEM or by the end-user as an audit check to verify that the supplier or its own production manufacturing is meeting the product requirements. These test stands can check every component or a sampling of parts. These "one-off" test stands can be operated by hand or built for a specific "in-line" requirement. Most FlodraulicGroup ATP test stands can also be configured for QTP testing when the part goes into production.

Production Testing:

Flodraulic Group can assist you with production testing, also known as "End-of-Line" testing, on any type of part coming out of your manufacturing process. This high quality testing provides 100% testing for various parts to meet your production requirements. These generally large and complex automated test systems are a key to meeting your quality requirements.

Failure/Warranty/Exception Testing:

These tests are performed to determine the cause of problems associated with a part during the full production process. These are generally performed on QTP test systems.

Support Systems:

Flodraulic Group also offers several lines of add-on components or systems to complement your testing requirements, including:

- Special testing manifolds

- Hydraulic attenuators

- Fluid testing equipment

- Pump back systems

- Fluid conditioning systems

- System controls / upgrades / monitoring

- Data acquisition systems

- Temperature chambers